Tapered Pilots Heavy Duty Pilots for Die Stamping Standard Lifters

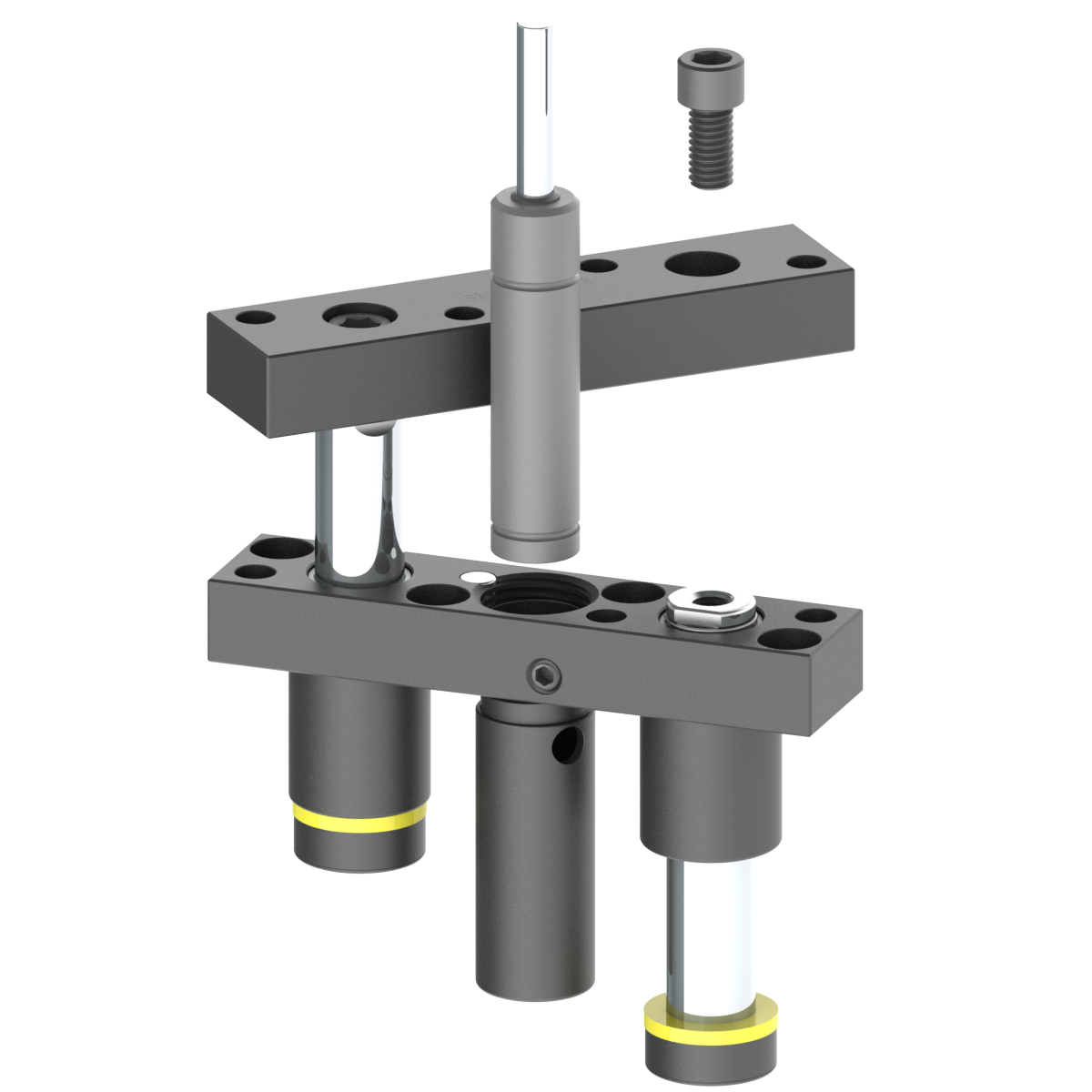

Dampener to reduce impact force. Standard Lifters' component integration into the tooling designs is second to none. The Guided Keepers are a game changer for guidance and retention in one, as well as the most robust design across the board.

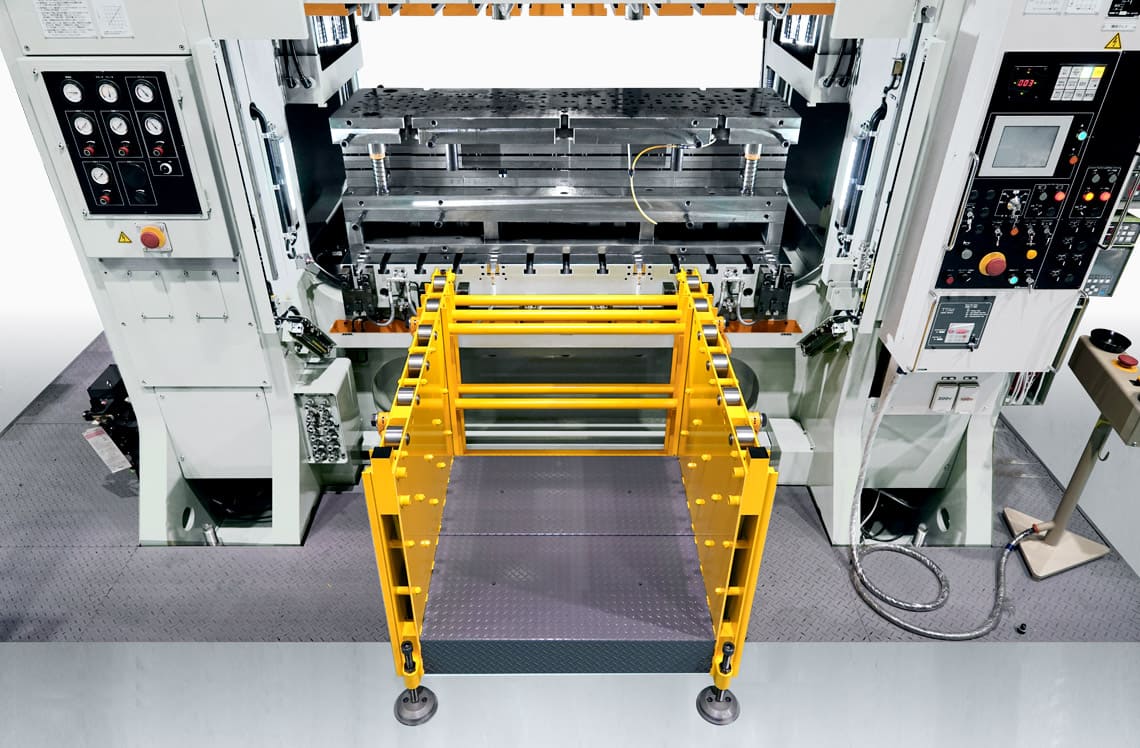

BRUDERER UK High Speed Mechanical Stamping Presses SWISS MADE

Pascal offers a number of safe hydraulic press components to suit your specific needs, including die changers, die carts, die lifters and pre-rollers. Placing the die in position in the metal stamping press, securing the die clamps, and performing a die change manually can take a lot of time. Time wasted on die change can affect delivery.

Tapered Pilots Heavy Duty Pilots for Die Stamping Standard Lifters

About Pacific Metal Stampings, Inc. Since 1968 Pacific Metal Stampings has specialized in producing metal components for hundreds of aerospace, automotive, electronic, military, green technologies, and industrial customers.We operate 27 punch presses, ranging in size from 22 to 165 tons, which produce simple and complex shapes from dies produced in our own tool and die department.

Tapered Pilots Heavy Duty Pilots for Die Stamping Standard Lifters

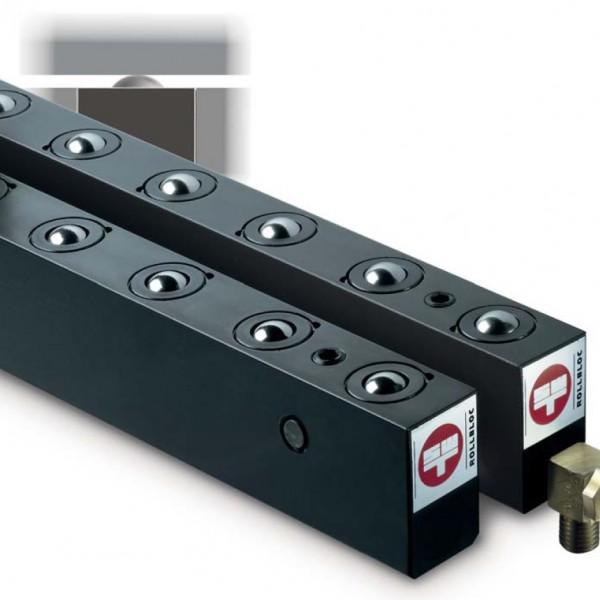

To lift, move, position and lower heavy dies on vertical presses, like stamping presses and vertical injection molding machines. Advantages Clean operation Minimum effort Faster operation With or without power to be operated Hydraulic ball bar die lifter system EAS SMB springloaded mechanical die lifter balls Hydraulic ball bar die lifter system

BDC Machinery Quick Die Changes (Hydraulic)

Die Handling Solutions. Click below! ROEMHELD Hilma offers the widest line of die clamping and handling systems in the industry for applications with mechanical presses, hydraulic presses, forging presses, injection molding machines, and die-cast machines. Some of the various products include die carts, die consoles, and die lifters (hydraulic.

Hydraulic Stamping Solutions, Press Machine Components

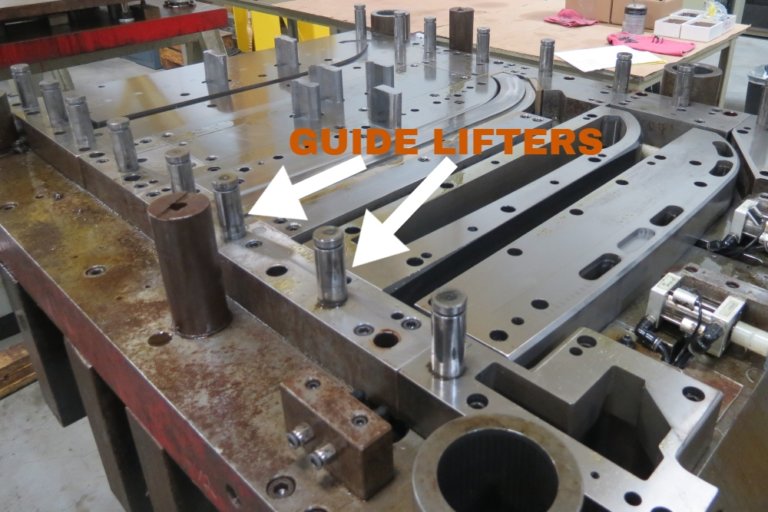

Many stamping die components such as strip guiding are usually produced in small quantities, which is quite expensive and time-consuming.. The strip guiding rail is always used in combination with a strip lifter. Thanks to the screw connection on the top, it can be directly installed from the working plane. The hardened design ensures the.

Die Lifters LHS

In stamping applications, it can be beneficial to bring in another set of eyes to provide a neutral site assessment of your lifting and rigging equipment and procedures. A third-party can evaluate your lifting program and practices as they pertain to the applicable OSHA and ASME standards.

Three Important Things to Know About Metal Stamping as you Design a Metal Part Ultra Tool

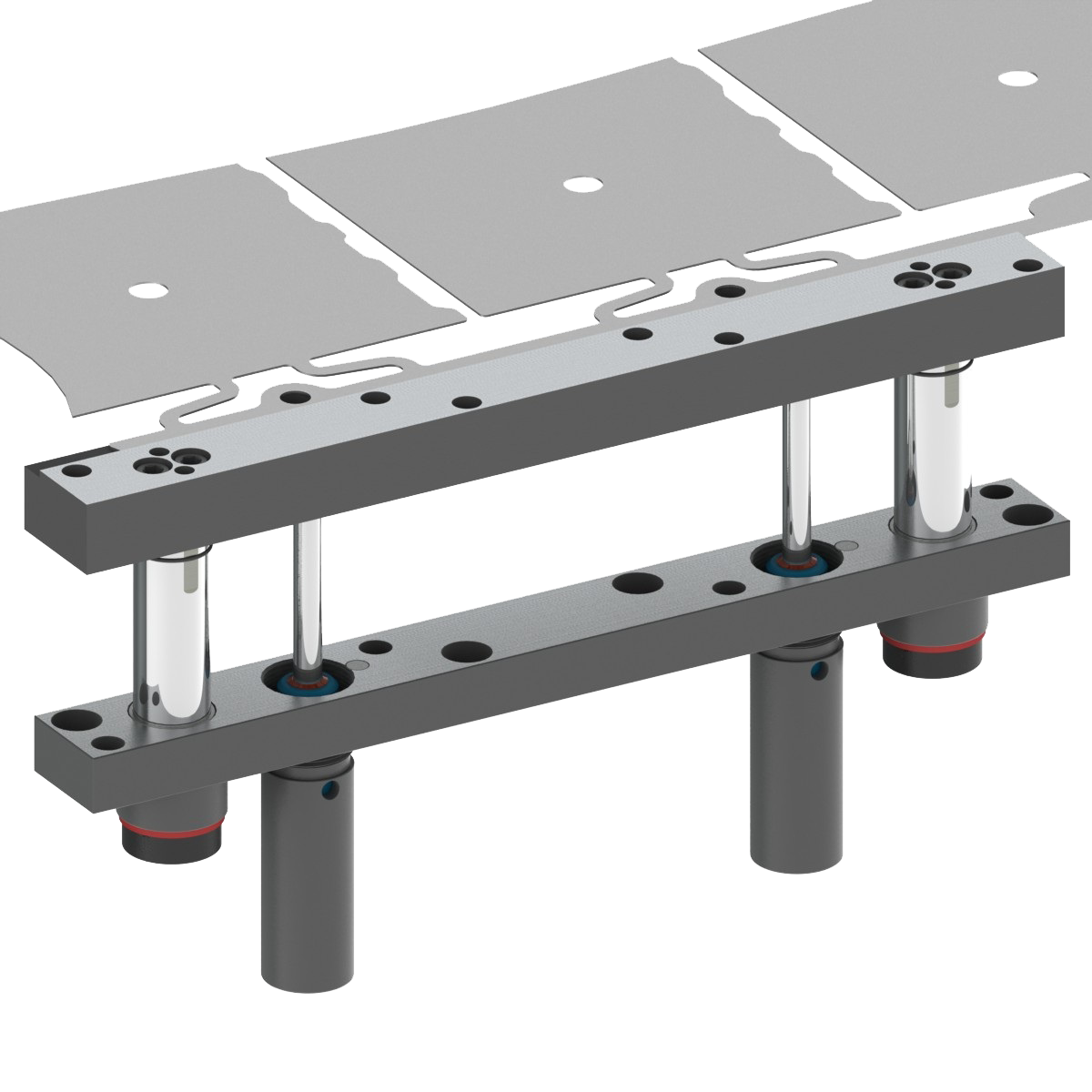

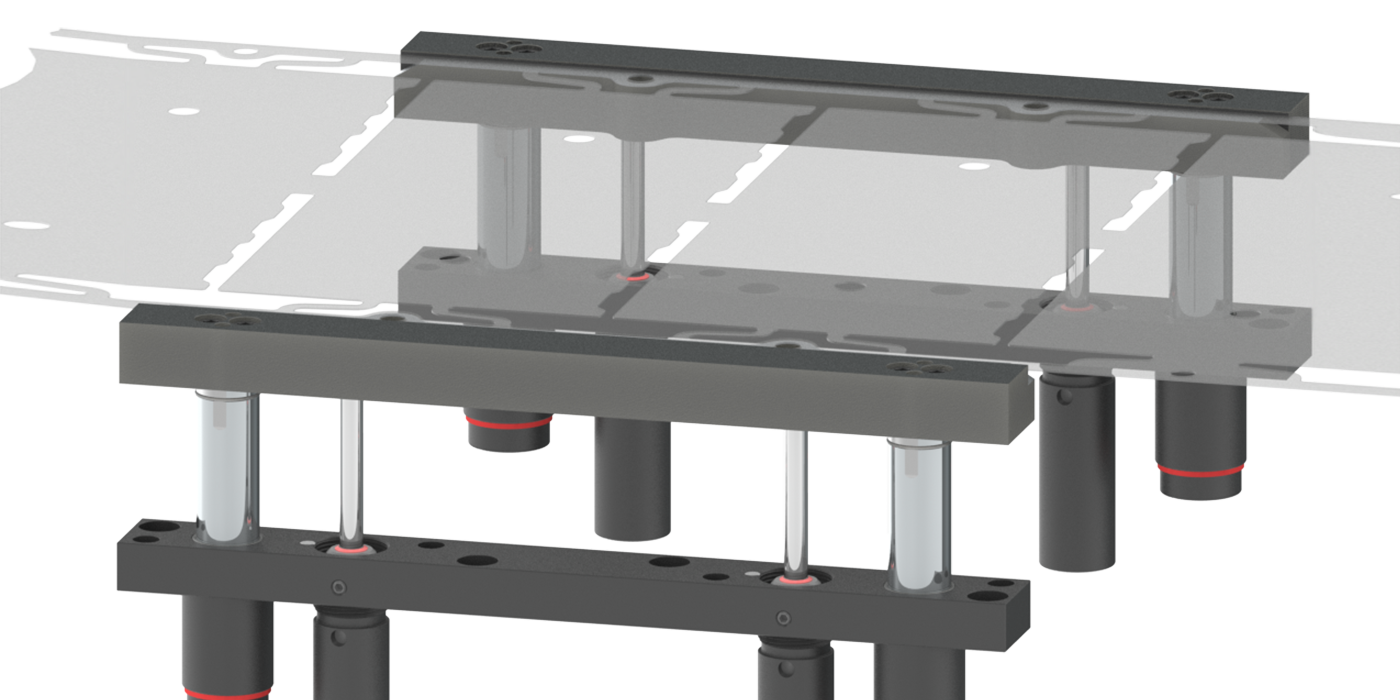

These lifters include built-in guidance for single, multipoint or rail lift applications and are ideal for progressive stamping dies. All three force models (0.1 ton, 0.2 ton, 0.3 ton) are powered by DADCO's Micro or Mini nitrogen gas springs. Online Catalog Print PDF Nitrogen Gas Spring Rail Lifter Two Post Nitrogen Gas Lifters Flange Model

Rail Lifters Customizable Die Lifters Standard Lifters

Our innovations create more robust die assemblies, greater operating precision, and more uptime for stamping operations. The Standard Lifters difference We manufacture and inventory 99% of all our products, and we sell direct for greater speed. Rely on us for fast global delivery. Learn more Have any questions? Talk with us directly using LiveChat.

Rail Lifters Customizable Die Lifters Standard Lifters

Quick Die Change Hydraulic Clamps Hydraulic Cylinder and Rocker Clamps provide the cornerstone of a lean and well controlled Quick Die Change System. As the product the secures the die, flexibility in application and sizing is key to ensuring solid and consistent die clamping. PFA's variety of clamps and flexible heights cover all the options.

Standard Lifters Innovative Die Components.

Stamping Press Machines. Our automated quick die change equipment can improve changeover times and workplace safety. Pascal offers traveling clamps, die changers, pre-rollers, and die lifters. Manual operation might lead to simple mistakes such as forgetting to remove a clamp, resulting in damage to thousands of dollars worth of die materials.

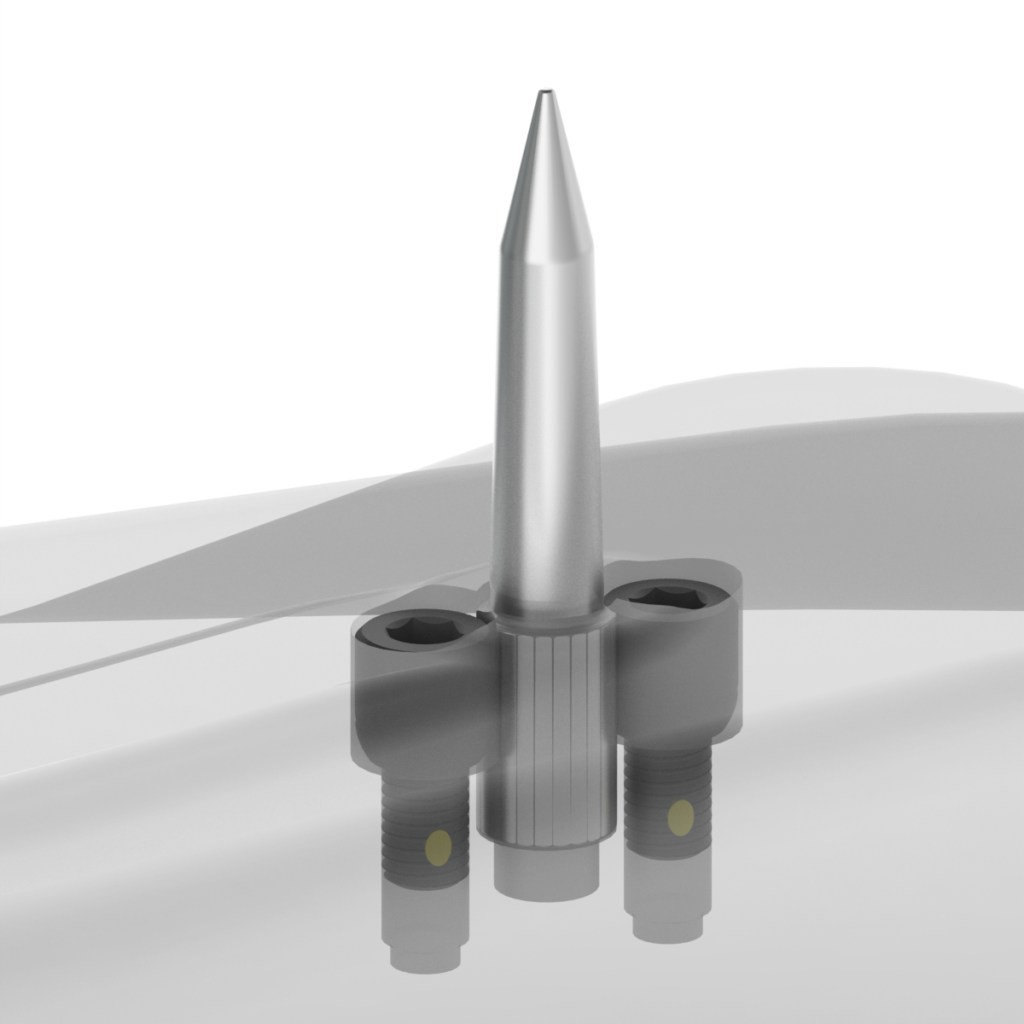

Die Lifters Archives Premitec

We also offer an innovative solution for stand-alone pilots for both progressive metal stamping and transfer stamping. Made from highly wear-resistant M2 tool steel, Standard Lifters Tapered Pilots offer a unique 3-degree lift transition taper that prevents stock binding while maintaining high strength.

Rail Lifters Customizable Die Lifters Standard Lifters

KOR-LOK ® Preloading Hydraulic Locking Cylinders and Quick Die Change (QDC) clamps are in-stock and ready to ship, so you can start saving time and money with SMED today. From spare parts to complex solutions, PFA is the answer to faster production and more profits. Use hydraulic die lifters when die weights are typically standard for medium.

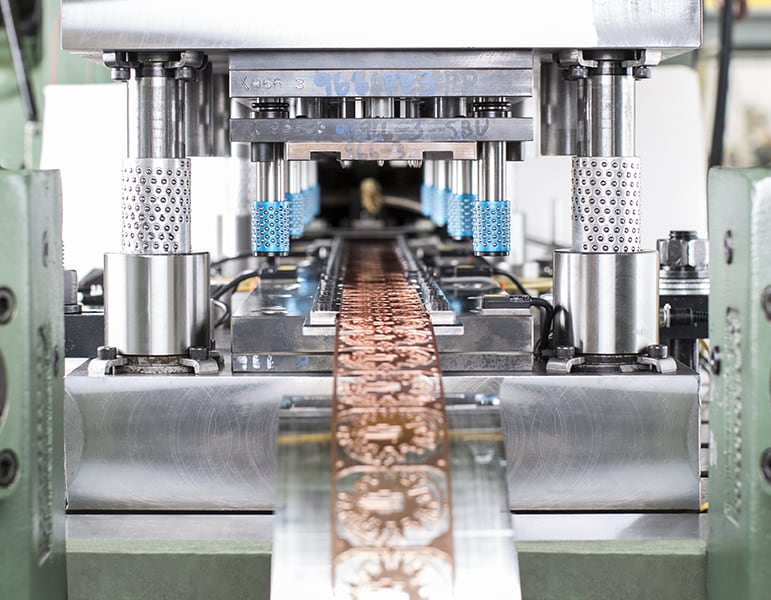

Progressive die stamping Highvolume sheet metal punching

Stamping Dies. Sheet - Steel - Brass - Stainless Steel - Copper - Galvanized - Aluminum - Spring Steel - Woven Wire Mesh and more. Stamping Dies Info. metal stamping. Helfrich Tool excels in producing a limitless variety and sizes of custom stamped metal parts used in industrial and commercial assemblies, all made to your exact specifications.

Tapered Pilots Heavy Duty Pilots for Die Stamping Standard Lifters

A quick die change system provides a way of swapping one die with another automatically, often referred to as smed, or single minute exchange of dies. Benefits of implementing a quick die changer system for press machine operations include: Perform more frequent changeovers with no loss of capacity Shorter production runs

High Precision, High Volume Metal Stamping Metal Stamping Manufacturer Wiegel

July 1, 2016 With all material running through progressive stamping dies we find the carrier—the material that connects, holds and transports the stampings from station to station as they move sequentially through the die.