Knurled PowerBlock Handles For Your Perfect Upgrade Bare Steel Equipment

When you need to cycle through large loads, the PC8000 has you covered. It was designed with input from mining operations around the globe to maximize productivity with 240-400 st trucks. Customizable for your operation. Rigorously engineered for durability. Sustainable, efficient Tier 4 Final engine.

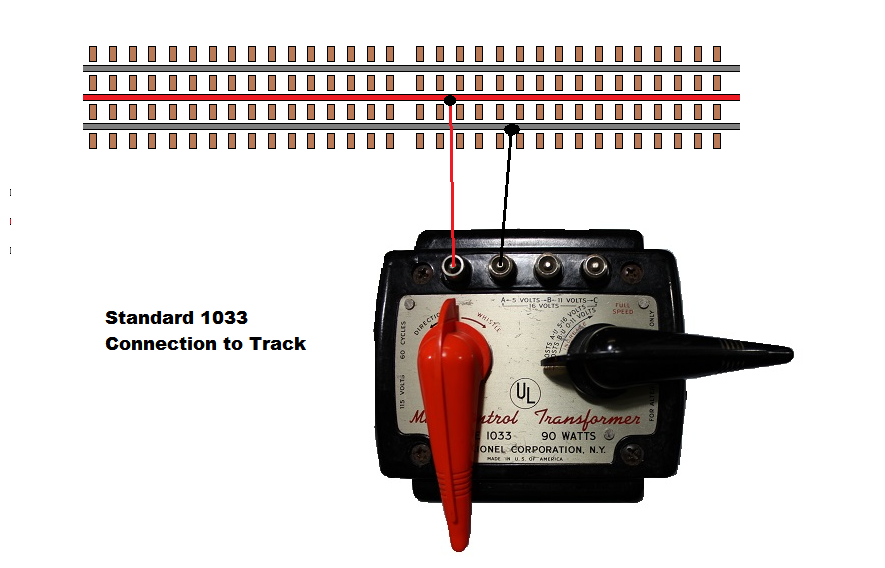

Electric Train Parts Diagram

The structure of the HPTS in the excavator is given as Fig. 3.In this system, an engine and an electric machine are adopted to co-drive pumps. The system uses the electric machine of high efficiency to balance the load fluctuation by working in motor mode and generator mode, to stabilize the working points of the engine in the high efficiency area, and then to improve the overall efficiency of.

How to Do a Power Clean 4 Steps for Beginners. Nike AU

An innovative powertrain is proposed for hybrid hydraulic excavator. • A gear box is integrated to adjust torque and speed of power source. • An online energy management strategy is proposed to improve the engine's efficiency. • Proposed system offers improvements in energy saving and regeneration up to 5.86% and 48.2%. •

GREENMAX N GAUGE JNR Kumouni 81 OitoLine Color 1car No Power 31659

To enhance the energy saving efficiency, this paper proposes an innovative electric hybrid hydraulic excavator, as shown in Fig. 1. The engine, electric motor/generator, invertor, battery, hydraulic pump, and planetary gear are installed in the powertrain of the excavator. The hydraulic motor and generator are installed in the return line of.

How to Train Others on Electrical Equipment Maintenance

Currently, there are several energy saving methods for HE and they mainly concentrate on the following three aspects: (1) improving the performance of working components; (2) reforming the hydraulic system; (3) ameliorating the situation of power matching between the diesel engine, the hydraulic system and the load.

Construction Machinery Parts 1994521/4575 1912535/2682 final drive GP

This paper systematically analyzed the performance of the powertrain hybridization of hydraulic excavator and compared the main performance among the parallel, the series and the conventional configurations based on a 5-ton excavator. The data of the conventional excavator used for analysis were gathered from the real working process, while.

Construction Machinery Parts 1994521/4575 1912535/2682 final drive GP

The main factor for low efficiency and high emissions of the traditional excavator is the low efficiency of the power train system. 1 Currently, the main method of improving the efficiency of the power train system is hybrid power train systems (HPTSs). 2 - 4 The HPTSs adopt two or more power sources to drive the load 5 - 7 and to make full use.

Construction Machinery Parts 1994521/4575 1912535/2682 final drive GP

The powertrain solutions that integrates the engine, hydraulic parts, controller, to provide customers with system solutions. Dual-pump design and Integral valve design, make the excavator structure compact, performance excellence. LSC hydraulic system, distribute according to demand, manoeuvrability better handling. Nr.

Electric Trains Diagram

This article reviews the state-of-art for the hybrid wheel loader and excavator, which focuses on powertrain configuration, energy storage devices, and energy management strategies. The basis of classification and characteristic of each powertrain configuration are described. Advantages and disadvantages of batteries, supercapacitors, hydraulic.

Research on the control strategy of power train systems for hybrid

In the series-parallel hybrid powertrain configura-tion of an excavator, the engine drives the generator directly. The hydraulic pumps are driven by generator in series, and the swing electric motor is driven by gen-erator and battery or supercapacitor in parallel.31 Although the fuel consumption of series-parallel hybrid

Power Up It's Time to Train Tee Zazzle

The electric excavator's powertrain system — provided by Danfoss Editron, a subsidiary of Danfoss Power Solutions — eliminates the noisy, dirty diesel engine in the 323F and replaces it with a battery pack and electric motor to power the excavator's hydraulic system.

Nearly 2 months after train crash, CTA Yellow Line set to reopen

Order Download Introduction During the excavator design, we need to consider several key factors, such as the special demand of the market, noise and emissions regulations, reducing costs while improving performance.

3+ Hundred Coal Train Loader RoyaltyFree Images, Stock Photos

Electric power train system is one of the energy saving technologies of excavator [3], [4], [5]. However, because of cost and reliability of batteries, the development of electric excavators is restricted.

At least 24 injured after NYC subway trains collide, derail; service

PC30MR-5. Horsepower 24.4 HP @ 2,200 rpm. Operating weight 6,812 - 7,143 lbs. Bucket capacity 0.07 - 0.21 yd³. View all specs. Request a quote Find a dealer. Competitive comparison Download brochure Financing information Order parts.

CNH Industrial completes delisting from Euronext Milan and begins

To reduce the energy consumption and emission, an innovative powertrain and the energy management strategy are proposed for hydraulic excavator in this paper. The novel powertrain consists of the engine, motor/generator, planetary gear, gearbox, and variable hydraulic pump. The energy regeneration system is also applied on the system to regenerate the potential energy and charge the battery.

3+ Hundred Coal Train Loader RoyaltyFree Images, Stock Photos

This paper studies on parameters matching and control strategy of power train systems for hybrid hydraulic excavators (HHEs). Load profiles of a 20-t excavator are measured and analyzed.